SxS racing builds and sport quad parts stacked to the roof! Story and photos by Jeff Henson

The last time I was at Lone Star Racing (LSR) was right around the turn of the century. I broke and welded up the stock swingarm on the ’86 TRX250R so many times while racing that I finally broke down and bought an aftermarket swingarm. LSR has changed considerably over the years, especially after adding side-by-side parts to the menu and now building race cars from the ground up. My chin hit the floor as I walked into the 50,000-square-foot warehouse, which was buzzing with the sounds of steel grinders, chop saws and TIG welders.

BUILT FOR RACERS BY RACERS

A familiar face met me at the door. It was my old racing buddy, Jonathan McVay, whom I raced desert against for several years on ATVs. McVay gave up ATV racing about a decade ago for a cage. He didn’t give up desert racing, but he does it behind the wheel of a high-dollar Polaris RZR RS1 with the full LSR treatment now. McVay has been a long-time believer in the quality of LSR products—a frequent customer—and now he works for the company in sales.

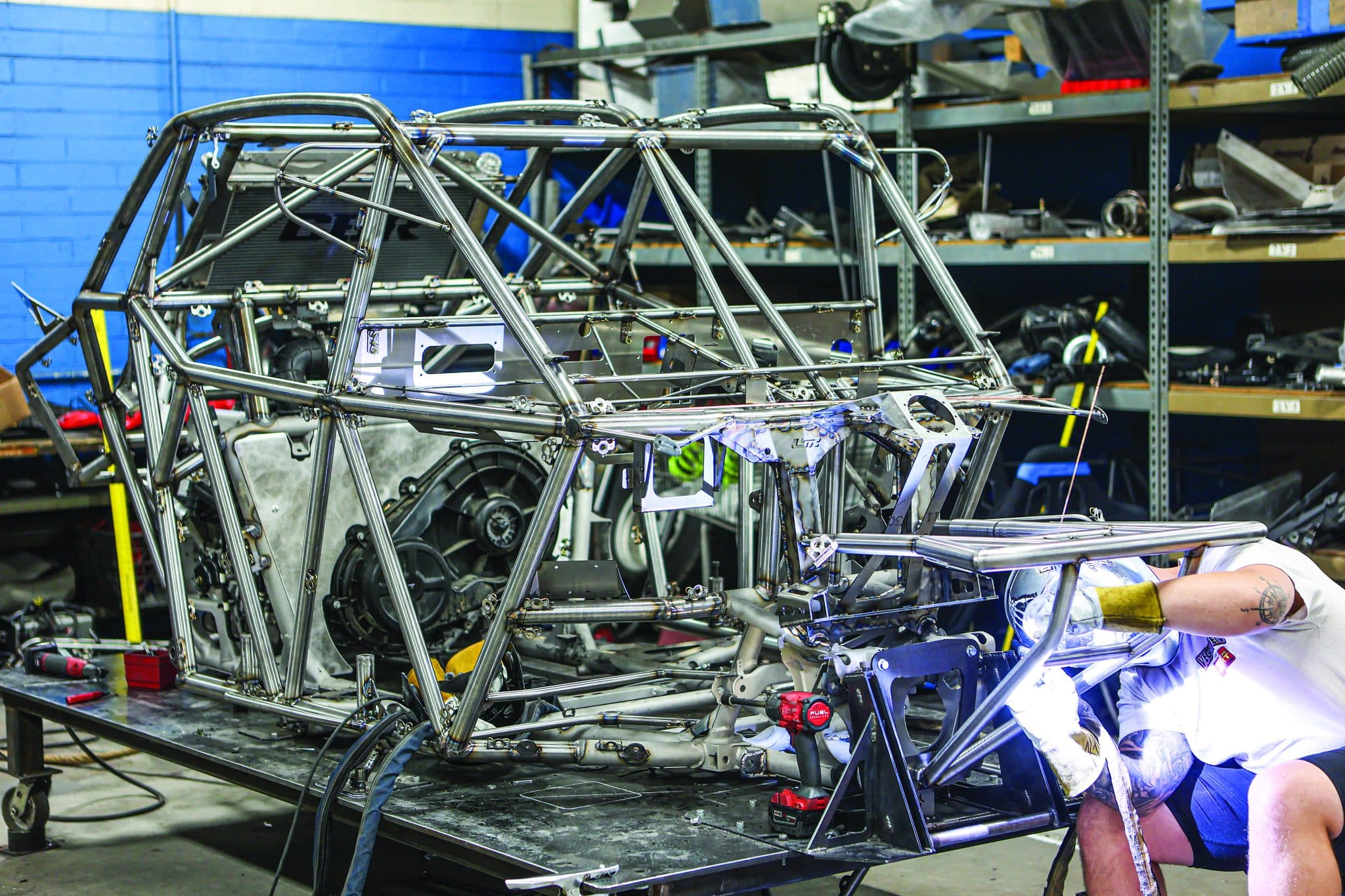

“My original race car was the third one built by Lone Star, but the difference between the lines of what we were building 10 years ago and what’s being built today is so infinitely different. They’re just so much more attractive,” said McVay as we walked by the assembly area where a few Pro Rs and X3s were being assembled and/or race-prepped.

CHOP SHOP

“We have several Pro R builds going on right now. All the ones we have in here today are desert racer builds for professional racers, but a week ago, the shop looked completely different. We have multiple jigs for different race cars, but every single car is custom-built. No two are absolutely identical,” claimed McVay.

Full builds run from $100,000 to $120,000 with every off-road racing feature you can think of. One option I found particularly impressive was seats that adjust electronically. In the event of a breakdown or flat tire, the driver and co-driver can lower the seat to loosen up their race harnesses. Once back inside, they don’t have to fumble with readjusting the belt and killing valuable time—just latch back in and raise the seat back up until you’re snug. It’s the little things that impress me, but the cars as a whole look ready to go to war. “You’re basically buying a low-end Ferrari, so it better look good,” McVay said with a laugh.

MADE IN THE USA

All race car chassis are built in the shop using heavy-duty chromoly steel. For safety reasons, mild steel is never an option. The chassis is built to take a beating while protecting the occupants from a worst-case racing scenario.

“Everything with the Lone Star name is built right here in Mesa, Arizona. Nothing comes from overseas. All welding, and even powdercoating, happens in this building,” claimed McVay. Every department had workers focused on a variety of tasks, whether it was welding, bending steel tubing, operating machinery or packing orders for shipping. There was a very controlled and efficient sense of urgency everywhere I looked.

SPORT QUADS ARE ALIVE AND WELL AT LSR

We walked into a department where I spotted rows and rows of sport ATV tooling. “This room has every possible jig you can think of. We’ve got steering stem jigs, A-arm jigs, swingarm jigs. We have negative 2-inch swingarms, negative 1 inch, all the way up to plus 6. We just have so many variables and so many options for our customers,” said McVay.

As we rounded a corner into LSR’s CNC department, I was elated to see the mass production of numerous sport ATV parts—more axle-bearing carriers than I could count. “This makes me happy,” I exclaimed. “Obviously, the aftermarket for sport quads is doing just fine for you to have this much product.” McVay responded, “Look at all of these wheel hubs. We can’t keep them in stock! A lot of the time we’re sold out before the product is even built. It’s the reason I always encourage customers to order spares.”

Sport quad axles were stacked in numerous locations, along with lengths of the raw material that would soon become axles. Lone Star still offers a lifetime warranty on sport ATV axles. “We always require the customer to send us the axle, and if we can’t straighten it, we’ll replace the axle. We just ask the customer to pay shipping both ways.” McVay showed me the machine that straightens axles. It’s impressive—and massive! We’ll be shooting a video of the process soon, so watch for that video on the Dirt Wheels website.

Another worker was turning out rows of new footpegs to be assembled with LSR’s DC Pro nerf bars. “As you can see, we still build a lot of ATV stuff,” said McVay. A-arms, steering stems, nerf bars, tie rods—we shouldn’t be surprised since we hear the same from every manufacturer of sport ATV parts; business is good! But, it’s not just parts for the more modern four-stroke ATVs like the YFZ450R.

TWO-STROKES, TOO!

“We still sell tons of Honda TRX250R stuff, you wouldn’t believe it! It’s crazy,” said McVay. And, it’s not just the small parts. LSR is still selling complete frames for the Honda 250R, as well as other sport quad models. In fact, they sold three Yamaha Banshee frames the week of our tour. McVay continued, “Honest to goodness. We’re having a hard time keeping up with demand.”

Imagine the aftermarket job creation that would evolve if the major powersports players wised up and started building sport quads again. It could happen!

For more information about Lone Star Racing, check them out online at www.lsracing.com.